Raman spectrometer

A Simple Explanation of Using Raman Spectroscopy to Examine Component Structures

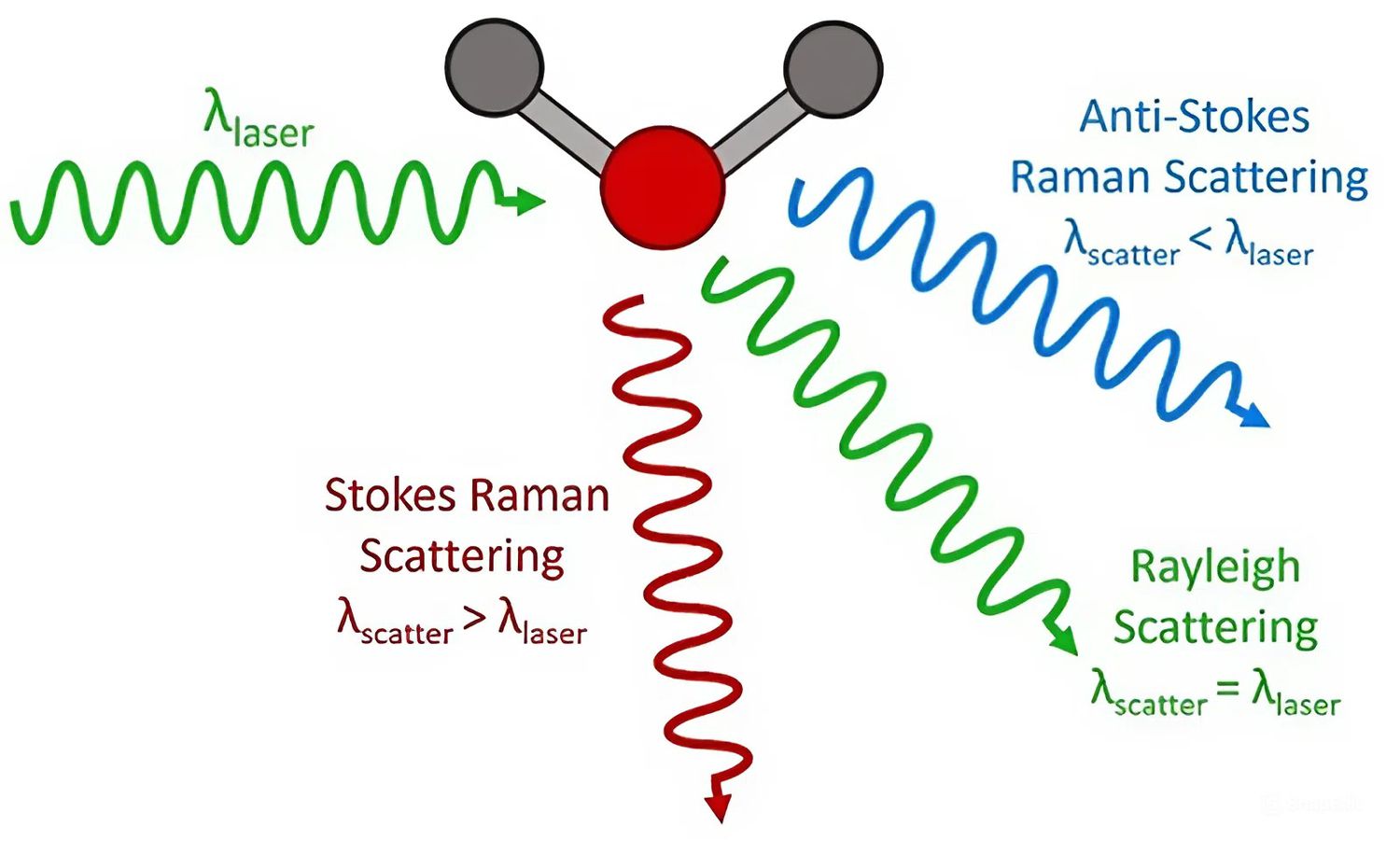

In practice, determining whether there are issues inside a piece of silicon or a semiconductor material cannot be done by visual inspection alone. Raman spectroscopy uses a laser beam directed at the sample and then collects the atomic vibrations within the material. These vibrations carry characteristics unique to each substance, allowing technicians to identify the material composition and its level of purity without cutting or damaging the sample.

In laboratories and chip manufacturing facilities, Raman spectroscopy helps quickly detect impurities that arise during processing. Instead of relying on subjective judgment, operators observe the spectral bands displayed on the screen to assess the quality of materials such as silicon or graphene. This method keeps component surfaces intact because there is no physical contact during measurement.

Monitoring Crystal Grain Conditions with Raman Spectroscopy Equipment

During heating or annealing processes used to form thin silicon films, crystal grains may sometimes arrange unevenly and become twisted or overlapped. If these irregularities are not detected in time using Raman spectroscopy equipment, they can cause unstable operation or reduce the lifespan of components. Systems such as the Anton Paar Cora 5001 Fiber allow these changes to be observed at a very fine scale through laser wavelength analysis.

In addition, structural defects such as microscopic voids in SiC crystals can be clearly visualized using Raman spectroscopy through two-dimensional distribution maps. Based on the collected data, operators can adjust annealing temperatures so that crystal grains are arranged more uniformly. This level of control helps reduce defective products and ensures component durability in real-world applications.

Reviewing Charge Carrier Density Through Raman Spectral Analysis

The density of charge carriers inside diodes or p–n junction regions is often not uniform across the entire surface. If this distribution varies too much, the electrical parameters of semiconductor components can deviate from their intended specifications.

The spectral data obtained enables technicians to adjust impurity concentrations to match the original design requirements. For large semiconductor ingots, analysis along multiple cross sections ensures that carrier concentrations remain within acceptable limits. This approach helps production lines operate consistently and minimizes errors caused by dopant concentration variations.

Choosing the Right Raman Spectroscopy System at EMIN

Depending on each production stage, from incoming material inspection to final product evaluation, the requirements for Raman spectroscopy equipment vary. Technicians who frequently move between production areas for on-site inspections often prefer handheld models such as the Anton Paar Cora 100 due to their compact design and ease of use. Despite their small size, these devices still deliver clear spectral results to support immediate decision-making at the point of inspection.

By contrast, for in-depth analysis and applications requiring complex data visualization, benchtop Raman spectroscopy systems such as the Cora 5001 series are more suitable. With high data acquisition speed and sensitive sensors, these systems convert atomic vibrations into intuitive and easily analyzable data. Replacing manual inspection steps with spectral measurement methods makes workflows more proactive and reduces production risks.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-