Suneast UXT-810 回流焊炉 (Dual tracks, 10 heating zones, 20 heating modules)

制造商: Suneast Model: UXT-810 P/N: Dual tracks - 联系

Heating system

- Heating zone structure: 10 heating zones, 20 heating modules

- Heating zone length: 3670mm

- Heating up time: 25min

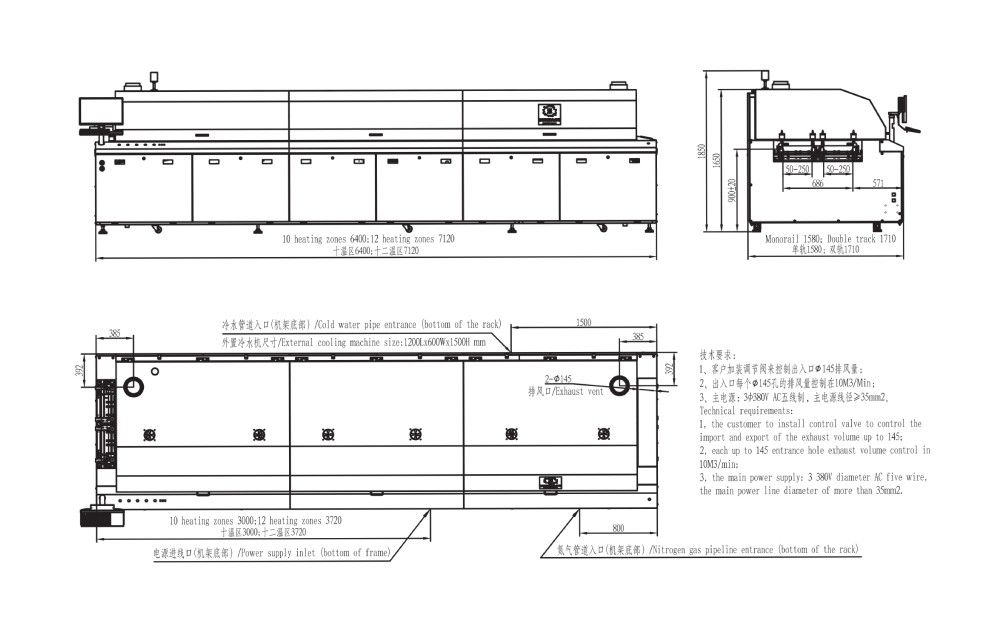

- Outlet Exhaust Diameter,valume: 2-Φ145,Exhaust demand 10m³/min x2

Cooling system

- Cooling type: Three cooling zones:forced water cooling

- Cooling zone length: 1250mm

- Chiller power: 5P Water chiller

Conveyor system

- Conveyor Type: Chain + mesh belt synchronous transmission

- Conveyer Direction: L→R,R→L

- Converyer Height: 900±20mm

- Component Height: Clearance above 30mm, Clearance below 25mm

- Conveyor Speed: 300mm-2000mm/min

- Guide rail structure: Dust free special hardened guide rail

- PCB Width: min 50mm-max 250mm (Dual tracks); min 50mm- max 450mm (Single track)

- Fixed Rail Mode: The front and rear guide rails are fixed, and the middle two guide rails are movable

Control system

- Power: AC3Ø 5W380V 50/60HZ

- Total Power: 96KW

- Startup Power: 38KW

- Normal consumption: 11KW

- Temp Control Range: Room temperature to 320℃

- Control type: PC+PLC Control system

- Temp Control accuracy: ±1℃

- PCB Temp Deviation: ±2℃

- Data Storage: Process Data and status stotage

- Power Outage Protection: Equipped with UPS

- Operation Interface: Windows Chinese simplified, English online free switching

- MES: Standard

- Computer: Commercial computer

General

- Dimension(LxWxH): 6400*1710*1650mm

- Weight: 2900-3100kg

- Flux recovery system: Standard

- Color: Bright wrinkled white

◆High heat energy, low energy consumption, high power motor matching wind wheel,theoretical and practical verification; under the same conditions set, can ensure the small and large components to achieve the minimum heat absorption difference,and achieve the best thermal balance;

◆The latest thermal insulation technology and the new furnace structure design can effectively reduce the furnace surface temperature and reduce the heat loss;

◆Imported PLC program controller, stable and reliable performance,high precision of temperature control and curve repetition;

◆Double-sided guiderail with special hardening treatment, strong and durable,repeatable use, cost saving up to 50%;

◆Online maintenance of rosin recycling system, modular design,convenient maintenance, reduce maintenance time;

◆Patented hotair system, hotair convection conduction more efficient, faster heat compensation;

◆Built-in real-time monitoring system of furnace temperature,which can automatically generate furnace temperature curve(option) ;

◆Intelligent data can be traced and uploaded toMES system.

- 质量承诺

- 正品保修

- 送货到家

- 交易简单化